Cleaning and Maintenance

The Best Way to Clean Your Flooring Product

Flooring and Tile Maintenance

212 Carpet has the most acceptable sustainable cleaning and maintenance options available in NYC - call us for a quote.

Last year, when COVID-19 became a worldwide pandemic, it changed everything, including Cleaning and Maintaining floors.

We also now offer the Clorox Total 360 Disinfectant Cleaner as part of our Flooring and Tile Maintenance packages, which are offered only to our existing clients.

What is a Maintenance Package?

At 212 Carpet, we offer "FLOORING & TILE MAINTENANCE PACKAGES" only for our existing clients for flooring that we have supplied and installed.

We offer several different options, which are all customizable for each client, depending on their needs and budget.

What are the different options for the maintenance packages?

Clorox Total 360 Electrostatic Spray System Package

The number one maintenance package is the Clorox Total 360 Disinfectant Cleaner Package, which uses the Clorox Total 360 Electrostatic Spray System.

Applying this spray disinfects and kills the SARS-CoV-2 Coronavirus (COVID-19), cold, flu viruses (Rhinovirus), MRSA, and Norovirus in 2 minutes or less. The spray also eliminates Odors.

Clorox Total 360 Disinfectant Cleaner (EPA Registration 67619-38) appears on US EPA's List N for Use Against SARS-CoV-2. The EPA has stated the following:

"EPA expects the products on List N to kill SARS-CoV-2, the coronavirus that causes COVID-19 because they:

- Demonstrate efficacy against the coronavirus SARS-CoV-2 (COVID-19);

- Demonstrate efficacy against a pathogen that is harder to kill than SARS-CoV-2 (COVID-19); or

- Demonstrate effectiveness against a different human coronavirus similar to SARS-CoV-2 (COVID-19).

EPA expects all products on List N to be effective against SARS-CoV-2 (COVID-19) when used according to label directions."

This is the link to list N:

https://www.epa.gov/sites/production/files/2020-06/documents/sars-cov2_listn_06122020.pdf

Green Package

We offer a green waterless deep commercial carpet cleaning that is non-toxic, eco-friendly, and safe to return to the area immediately once completed.

Touchup/Repair Package

Touchup and repair package is for existing clients with high traffic at the location, which requires the replacement of carpet tiles, carpet wall bases, and reducers.

Customizable Packages

Any of the packages can be combined and customized depending on the clients' needs and budget. Pricing will vary depending on the frequency, size, and traffic. Please contact us for a free quote.

CARPET: A SUSTAINABILITY SUCCESS STORY

The carpet industry has succeeded in making carpets more sustainable and environmentally responsible than ever before. As almost all commercial carpet is certified as Green Label Plus, you can be sure that the carpet you select emits the very lowest VOCs possible. The GLP testing program meets or exceeds all regulatory requirements for emissions, including CA 01350, and is accredited by the American National Standards Institute (ANSI) to ISO Guide 65 specifications.

Meeting the Environmental Standard

Architects, designers, and end-users seeking environmentally preferred building materials can now identify carpet that has a reduced environmental impact through the ANSI/NSF 140 Sustainability Assessment for Carpet. NSF International has been developing public health standards and certification programs since 1944. ANSI/NSF 140 was the first multi-attribute ANSI-approved standard for environmentally preferred building materials. ANSI accreditation is a further assurance that the products tested and certified by CRI are green building products that meet high standards for indoor air quality.

LEEDing Into the Future

GLP-certified products, including carpet, are recognized by the US Green Building Council’s LEED version 4 standard as a Low-Emitting Materials Third-Party Certification and can contribute one point to a building’s LEED score.

Projects can also earn LEED credits by incorporating salvaged materials—such as refurbished, reused, or recycled carpet—into plans for new construction or renovation. Recycled content carpet meets the same industry performance standards and carries the same manufacturer warranties as carpet without recycled content.

Taking CARE to Recycle

Carpet manufacturers are voluntarily reducing the amount of old carpet that ends up in landfills. Through the Carpet America Recovery Effort (CARE), carpet companies, government entities, and product suppliers are developing market-based solutions for the recycling and reuse of post-consumer carpet. Carpet materials are put back into carpet production or turned into building materials and auto parts.

Green Building Supplies:

Green building is now a mainstay. Recognizing the benefits of building green are schools, healthcare facilities, businesses, public facilities. Governmental entities are passing laws mandating the future green construction of private and public buildings.

Contributing to green buildings in two fundamental ways are carpet, carpet pads, and carpet adhesives. This helps reduce volatile organic compounds (VOCs) and emissions and contributes to the growing use of recycled content for building materials.

It is vital to do everything possible to maintain indoor air quality, especially for new construction and renovation, since people spend about 90% of their time indoors.

The first in the flooring industry to study their indoor air quality effects in schools and commercial settings was the carpet manufacturers. Evaluated was carpet’s role in the indoor environment what resulted was the Green Label and the Green Label Plus programs. These programs tested and certified low emissions from carpets, cushions, and adhesives.

Green Label

Today, indoor air quality (IAQ) is an important environmental consideration, especially since we spend approximately 90 percent of our time indoors. In 1992, CRI launched its Green Label program to test carpets, cushions, and adhesives to help specifiers identify products with very low VOCs (volatile organic compounds) emissions. CRI has recently launched its next series of improvements called Green Label Plus for carpet and adhesives. This enhanced program sets an even higher standard for IAQ and ensures that customers purchase the very lowest emitting products on the market. Using scientifically established standards, the Green Label Plus program symbolizes the carpet industry’s commitment to a better environment for living, working, learning, and healing.

• Green Label and Green Label Plus ensure that customers are purchasing among the lowest emitting carpet, adhesive, and cushion products on the market.

• CRI designed the Green Label and Green Label Plus programs for architects, builders, specifiers, and facility managers who want assurances that carpet and adhesive products meet the most stringent criteria for low chemical emissions.

• Green Label Plus represents the fourth time the carpet industry has voluntarily enhanced the IAQ standard for its products.

Green Label Plus

Green Label Plus is an example of CRI’s leadership in the best practices of environmental responsibility. Look for the CRI Green Label Plus logo as proof that the product has been tested and certified by an independent laboratory and has met stringent criteria for low emissions.

Air Quality Sciences, an independent laboratory, tests carpet and adhesive samples using the most up-to-date, dynamic environmental chamber technology. The test methodology was developed in cooperation with the US EPA and adopted by the American Society for Testing and Materials (ASTM) as D5116 – Standard Guide for Small-Scale Environmental Chamber Determinations of Organic Emissions from Indoor Materials/Products.

Recycling Products to Make Carpets:

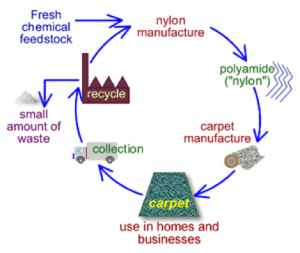

The amount of old carpet that ends up in landfills each year is a concern of the carpet industry. Carpet manufacturers are recycling old carpet materials back into production, recycling old carpet into alternative uses such as building materials, auto parts, refurbishing old carpet into new carpet tiles, reclaiming old carpet so it can be reused or recycled.

Through the Carpet America Recovery Effort (CARE), carpet companies, government agencies, and product suppliers develop market-based solutions for recycling and using post-consumer carpet.

Industrial Waste:

Efficient manufacturing reduces excess carpet waste, such as selvages, trimmings, and shearings. The carpet industry found a creative use for carpet by-products, such as carpet trim, yarn scraps, to avoid local landfill use. Examples of the recycling of carpet products:

-Recovered for use in other products are fiber and yarn that cannot be reused in manufacturing.

-Rugs and mats are cut from excess carpet and sold for other uses.

-Waste carpet trimmings, backing, yarn are sold to recycling plants to be processed into carpet cushions, furniture battings, and cushions, reinforcing filler for concrete, fence posts, road underlay, plastic lumber, automotive parts.

-Polyethylene packaging used to wrap carpet yarn spools and other raw materials are recycled into plastic pellets, sold to extruders of film, plastic wrap, and plastic trash bags, or is used in molded items.

-Cardboard, paper, aluminum, wooden pallets, yarn cones, roll cores, liquid containers, raw material packaging, scrap metal, other materials used in the manufacturing process are reused or recycled.

Post-Consumer Carpet:

The tasks of collecting, sorting, and transporting used carpets are being addressed by carpet and fiber companies as well as individual entrepreneurs. Several companies are collection sites and the developing means to separate carpet components and recover polymers in place. The industry is working towards recycling fiber back into fiber and turning Nylon 6 into new fiber. Refurbishing used carpet modules are being done by some companies. Billions of polyethylene terephthalate (PET) plastic beverage bottles are currently being used each year to make polyester carpet fibers.

Addressing the challenges of post-consumer recycling, CRI has a committee of member representatives rallying industry expertise and resources. Included in the committee’s work is the development of an identification system of carpet materials to make the sorting of fiber and backing compounds easier and more efficient in the future. Many CRI member companies and many entrepreneurs around the country, are currently using this identification system, called the Carpet Component Identification Code (CCIC).